Key Takeaways

- Floor-Specific Wheel Selection: Different floor types, hard, soft, uneven, carpeted, or delicate, require wheels designed to prevent damage and optimize mobility.

- Material Matters: Polyurethane, nylon, rubber, stainless steel, thermoplastic elastomer, and Vulkollan wheels each offer benefits tailored to load, surface, and environmental conditions.

- Load Capacity is Critical: Ensure wheels can support the full weight of equipment and contents to avoid damage to both wheels and flooring.

- Maintenance and Noise Considerations: Soft or coated wheels reduce noise and vibration, enhancing comfort and safety for both users and surrounding environments.

- Environmental Resistance: For wet, chemically exposed, or extreme-temperature settings, choose corrosion-resistant or specialized wheels to maintain durability and performance.

Choosing the right wheels for your equipment or furniture significantly impacts floor protection and overall functionality. Whether outfitting carts, machinery, or office chairs, different floors require specific wheel designs and materials. Selecting the wrong type can cause scratches, indentations, or noisy disruptions, while the right wheels help prolong your flooring investment. Products like Blickle casters offer specialized solutions for nearly every flooring situation, helping to maintain both performance and appearance in your work or home environment.

Understanding the unique characteristics of your flooring surface is the first step toward selecting the optimal wheel. From the hardness of the material to daily wear conditions, your floor’s attributes dictate the wheel type that will glide smoothly and without damage. Choosing appropriate wheels protects floor integrity, prevents unnecessary repairs, and enhances the comfort and safety of everyday movement.

For businesses and households alike, informed choices deliver both immediate and long-term benefits. By considering the details outlined below, you can make sound decisions, reduce maintenance costs, and ensure seamless mobility for any equipment or furniture you need to move.

Understanding Floor Characteristics

Each floor type has properties, such as hardness, surface texture, and vulnerability to marks or abrasions, that directly affect how wheels perform. Hard floors like polished concrete or porcelain tile typically need wheels that will not scuff or damage the surface, while softer coverings like carpet or vinyl are more likely to develop ruts or snags if paired with the wrong wheel type. The sensitivity of your flooring to scratches, pressure points, and vibrations will determine both the material and design of the ideal wheel.

Recommended Wheels for Common Flooring Types

Hard and Smooth Floors

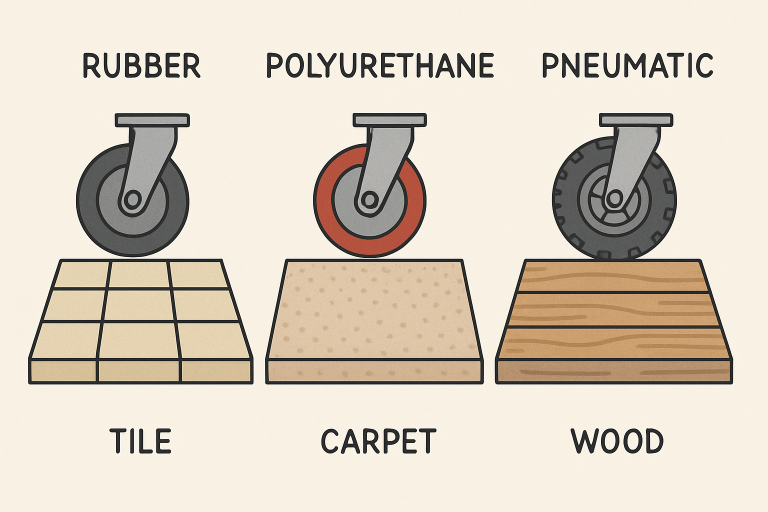

Floors made of concrete, tile, or glossy epoxy are best served by wheels that minimize wear and tear while gliding quietly. Polyurethane wheels are a top choice for these surfaces, as they distribute weight evenly, reduce abrasion, and are gentle on floors. Nylon wheels are also popular in industrial settings because they support heavier loads and resist cracking or flattening over time. For environments where noise control is crucial, soft rubber wheels effectively dampen sound and absorb vibrations, making them ideal for hospitals, libraries, and office buildings.

Uneven or Rough Floors

If your facility features surfaces such as asphalt, old wooden planks, or cobblestones, the demands change. Shock-absorbing wheels, such as those made from elastic rubber, protect both your equipment and the operator from jostling and vibrations. Pneumatic wheels filled with air are excellent for very uneven terrain, offering a cushioned, adaptive ride. For heavier loads and rugged use, solid rubber wheels combine resilience with load-bearing capability, maintaining stability even under continuous pressure.

Delicate Flooring

High-end floors such as parquet, luxury laminate, or quality PVC require a gentle approach. Soft polyurethane wheels roll smoothly and quietly, leaving no scratches or pressure marks. Thermoplastic elastomer wheels are another superb pick, valued for their high grip and wear resistance. For the quietest and most careful operation, select wheels with a soft rubber tread.

Carpeted Floors

Carpeted surfaces pose a risk of wheel sinking and snags. The ideal wheels are wide (at least 30mm) and have a large diameter (at least 50mm), preferably with a polyurethane coating. This width helps distribute weight and prevents the wheel from pressing deep into the pile. Avoid any wheel with an aggressive tread or a serrated pattern, as these can damage carpet fibers and make rolling more difficult. Instead, look for flat, shallow-grain wheels for the best performance.

Wet or Chemically Affected Floors

Every day or occasional exposure to moisture or chemicals, for example, in laboratories, cold storage, or some manufacturing facilities, calls for wheels that will not corrode or deteriorate. Stainless steel casters coated in polyurethane are optimal because they resist rust and perform well across a wide range of temperatures and conditions. Nylon wheels also perform admirably since they are impervious to water and many chemicals. For the most extreme settings, Vulkollan wheels offer exceptional durability and resistance to both wear and chemical exposure.

Key Considerations for Wheel Selection

- Load Capacity: Always ensure each wheel can comfortably support the full weight of your equipment and its load. Overloading will damage wheels and floors alike.

- Environmental Conditions: Choose wheel materials that withstand variations in temperature and chemical levels in your environment. Some materials harden in the cold or soften in high heat, leading to poor performance.

- Noise Levels: If silent movement matters, rubber or polyurethane wheels are quieter on virtually any surface compared to plastic or metal wheels.

Final Thoughts

Taking the time to match your wheel choice to your floor type not only safeguards the appearance and longevity of your surfaces but also improves ease of movement and safety in your environment. Assess your floors, consider the weight and conditions your equipment is subjected to, and review your options carefully. With careful planning, you can maintain a smooth, quiet, and damage-free operation while prolonging the lifespan of both your floors and the equipment you rely on every day.