Table of Contents

- Site Preparation

- Equipment Inspection

- Utility Connections

- Belt Installation and Alignment

- Polymer Preparation and Injection

- Sludge Feed System Setup

- Initial Operation and Adjustments

- Routine Maintenance and Monitoring

A belt filter press rental can provide cost-effective, flexible dewatering for short-term projects or emergency needs. Proper setup is essential to maximize operational efficiency and minimize delays, whether you’re handling municipal wastewater, industrial sludge, or other materials. A correctly installed belt filter press rental minimizes downtime, ensures smooth operation, and helps avoid costly complications.

Choosing a reliable equipment provider and understanding best practices for installation are the first steps in ensuring project success. Selecting the right location, prepping utilities, and closely following setup procedures protects your investment and supports your project’s goals. Before starting, it’s essential to review both the manufacturer’s and rental company’s manuals and safety documentation to ensure compliance with local regulations and standards.

Site Preparation

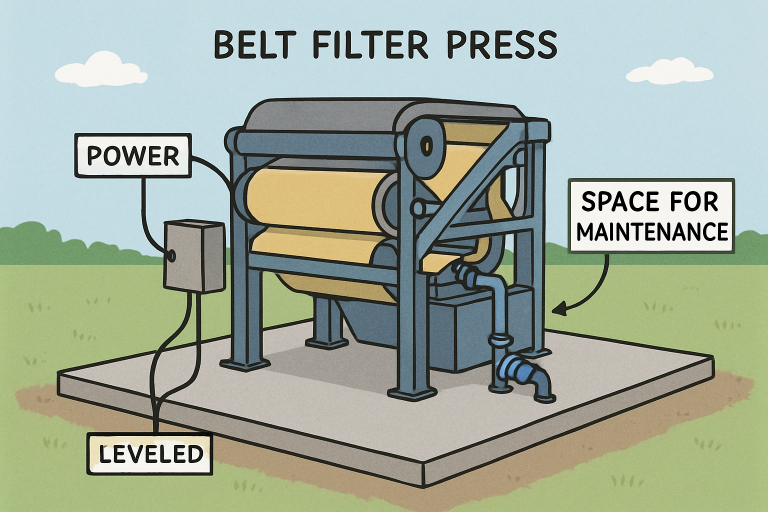

Start by identifying a location with a stable, level foundation capable of supporting the weight and operation of the belt filter press. Allow ample space around the equipment for maintenance, loading, and unloading sludge and cake. Site selection should also anticipate the need for vehicle access, nearby storage for chemicals and polymers, and unobstructed utility connections.

Ensuring reliable utility access is crucial. Your site should have electrical connections, water, and, if required, a source of compressed air. Poor site preparation can cause equipment instability, safety issues, and delays during setup and operation.

Equipment Inspection

Once your belt filter press arrives, carefully inspect all equipment and components for damage that may have occurred in transit. Check the belts for tears or excessive wear, verify that rollers, hydraulic systems, and electrical panels are intact, and compare delivered components against the provided packing list. Document any discrepancies with the rental provider before proceeding – this helps protect your interests and ensures operational integrity.

Utility Connections

Connect the belt filter press to the necessary utilities per the manufacturer’s specifications. Double-check that your power supply matches the unit’s voltage and phase needs – improper connections can damage the press or cause dangerous electrical issues. Secure a non-potable water connection for washing belts and preparing polymer solutions. If the press is equipped with components requiring compressed air, such as actuators or spray nozzles, ensure the air supply meets specified pressure and flow rates.

Belt Installation and Alignment

Proper belt installation is one of the most critical steps in setting up a filter press. Install filter belts according to the manufacturer’s step-by-step guidance, checking for correct orientation and tension. Misaligned or poorly tensioned belts can lead to tracking problems, increased wear, and poor dewatering performance. Set tension using a properly calibrated gauge and adjust alignment during the initial startup. Run new belts under low stress at reduced speed for 1-2 hours (known as “breaking in”) to help the belt settle and reduce the risk of wrinkling.

Polymer Preparation and Injection

Successful dewatering relies on the effective mixing and injection of polymer solutions. Based on lab data or supplier recommendations, select the right polymer type for your sludge. Follow the press’s instructions to mix the polymer to the correct concentration, then use the built-in or external polymer activation system to deliver the solution to the sludge feed. Uniform mixing increases floc size, improves filtration, and helps maximize cake dryness. Always consult material safety data sheets and handle chemicals with appropriate personal protective equipment.

Sludge Feed System Setup

Establish a reliable and continuous sludge feed by choosing a pump suited to your sludge’s viscosity and total solids content. Positive displacement pumps are common because they can provide a steady flow and handle coarser material. Balance feed rates using flow meters or variable speed drives to avoid overloading or starving the press, which can impact cake quality and reduce dewatering efficiency. Adjustments to the feed rate may be necessary during initial operation as system parameters are optimized.

Initial Operation and Adjustments

With all systems in place, begin running the belt filter press at a conservative speed and gradually introduce sludge and polymer. Carefully monitor key parameters: belt tracking, tension, sludge feed consistency, and polymer flow. Adjust operational settings in small increments, watching for signs of abnormal operation such as erratic belt tracking, overflow, or poor cake quality. Continuous observation during initial operation helps catch minor problems before they become costly downtime or equipment damage.

Routine Maintenance and Monitoring

Daily and weekly maintenance routines are crucial for reliable belt filter press operation. Regularly check and clean the filter belts to remove cake buildup that can reduce capacity and lead to mechanical failures. Lubricate rollers, bearings, and other moving parts according to the equipment manufacturer’s schedule. Monitor key performance indicators, including cake dryness, filtrate clarity, and belt condition. Early attention to small issues – such as tension loss, sludge leaks, or alignment drift – can prevent significant downtime and reduce repair costs.

Document maintenance activities and any issues encountered. This log helps inform future rental needs and operator training and supports efficient collaboration with equipment providers.